An IFR For Colorado Springs

Why the Integral Fast Reactor (IFR) could get a new lease on life in the shade of America's Mountain

The Integral Fast Reactor was a planned nuclear reactor concept, designed by Argonne National Lab between 1984-1994. Although it was cancelled, its innovations showed a reactor could extract ~100x more power from the same amount of fuel, while substantially reducing waste. It could make a comeback in Colorado Springs

Key Takeaways

80+ Years of Clean Energy: An Integral Fast Reactor (IFR) could provide Colorado Springs with reliable, carbon-free electricity for the next 80 years – a lifespan in line with modern nuclear plant planning (60–80 years). Operating without greenhouse gas emissions, it offers a long-term clean energy backbone for the city.

Massive Dispatchable Energy Storage: The IFR design (using TerraPower’s Natrium reactor) would integrate a large molten salt thermal storage system, acting as a “battery” to supply on-demand power. This allows the plant to store excess heat and deliver a surge of dispatchable electricity during peak demand or when wind/solar output dips. In practice, the reactor runs at steady output and charges the salt storage; when needed, the stored heat can boost output to ~150% of the reactor’s base power for several hours. This firm capacity enables greater expansion of intermittent renewables by providing a flexible backup that ensures grid reliability.

Dramatically Reduced Waste Longevity: By “closing” the fuel cycle and fissioning long-lived actinides, an IFR cuts down the hazardous lifetime of nuclear waste from tens of thousands of years to just a few hundred years. In a traditional once-through cycle, plutonium and other transuranics in spent fuel remain radiotoxic for 10,000+ years, challenging geologic disposal. In an IFR, those elements are recycled and destroyed for power, leaving primarily fission products that decay to safe levels within ~300 years. This greatly eases long-term waste management – the remaining high-level waste needs storage on the order of centuries instead of millennia.

No New Uranium Mining Required: An IFR can be fueled entirely with existing stockpiles of depleted uranium and spent nuclear fuel, eliminating the need to mine fresh uranium for decades. All the fuel needed for the plant’s lifetime (80 to 100 years) could be stored on-site at startup. The IFR’s fast neutron spectrum allows it to extract energy from uranium-238 and transuranics that conventional reactors cannot use, converting what was waste into fuel. According to Argonne National Laboratory, deploying IFRs would “eliminate the need for uranium mining (for centuries)” because of their ability to continually recycle fuel and consume depleted uranium. This fuel-self-sufficiency improves energy security and simplifies the supply chain – natural areas would be preserved from Uranium mining, fresh fuel shipments would be non-existent, and on-site fuel recycling would keep the reactor running for decades with little external input.

History of Sodium Fast Reactors

Sodium-cooled fast reactors have a rich history spanning from early experimental breeders to today’s advanced designs. Over the past 70+ years, each generation has built on lessons of the last, proving out the technology’s safety and potential:

“Zinn’s Breeder” – EBR-I (1951): The concept of using liquid metal coolant for a fast breeder reactor was pioneered by Dr. Walter Zinn at Argonne National Laboratory. In 1947 the U.S. approved construction of “Zinn’s breeder”, which became the Experimental Breeder Reactor-I. EBR-I was a sodium-potassium cooled fast reactor and in December 1951 it achieved a historic first – generating usable electricity (lighting four bulbs) from nuclear fission. It demonstrated the principle of breeding fuel (producing more fissile material than it consumed) and proved fast reactors could be a practical power source, helping launch the nuclear power era. EBR-1 suffered a partial meltdown after a miscommunication during a safety test in 1954.

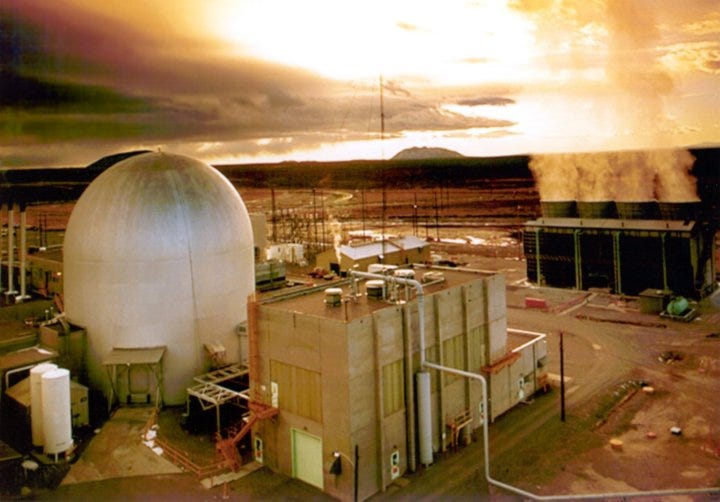

EBR-II (1964–1994): Argonne’s next step was the Experimental Breeder Reactor-II, a sodium-cooled fast reactor that operated in Idaho for 30 years. EBR-II produced 20 MWe and was the prototype for an integrated fast reactor system. It used a pool-type sodium design and metal alloy fuel, which provided inherent safety advantages. In April 1986, EBR-II famously demonstrated inherent safety by undergoing shutdown tests with no active intervention. Operators deliberately switched off cooling pumps and prevented control rod insertion (a simulated loss-of-flow accident without scram); the reactor’s passive physics safely brought power down and dissipated heat, with no damage. All such ATWS (anticipated transients without scram) tests were passed, “demonstrating the self-protecting characteristics of a metal-fueled fast reactor.” This was a watershed proof that a properly designed IFR-type reactor could survive accidents gracefully. EBR-II also was a workhorse for fuel experiments, successfully testing on-site recycling of its metallic fuel. Its 30-year run demonstrated the reliability of sodium fast reactor technology and did so with an excellent safety record.

IFR Program (1980s–1990s): The Integral Fast Reactor (IFR) project, launched at Argonne in 1984, sought to create a sustainable nuclear system combining a sodium-cooled fast reactor with on-site fuel reprocessing. The IFR used EBR-II as its test reactor along with a Fuel Cycle Facility to close the fuel cycle. By the early 1990s, it had met major milestones: demonstrating pyroelectric reprocessing (electrometallurgical recycling) of spent fuel, fabricating and burning new fuel containing recycled actinides, and developing waste forms for final disposal. It validated that all key pieces – reactor, fuel recycle, waste management – could work together. Notably, Argonne’s scientists showed that the IFR fuel cycle could be “integrated, [weapons]-incompatible, [and] proliferation-resistant”, keeping plutonium always mixed with other elements. Despite these successes, the U.S. government canceled the IFR project in 1994 just a few years before completion. This halted the momentum of fast reactor development in the U.S., even though the technical feasibility had been largely proven. The IFR’s legacy lived on in its designs and research findings, which would inform future projects.

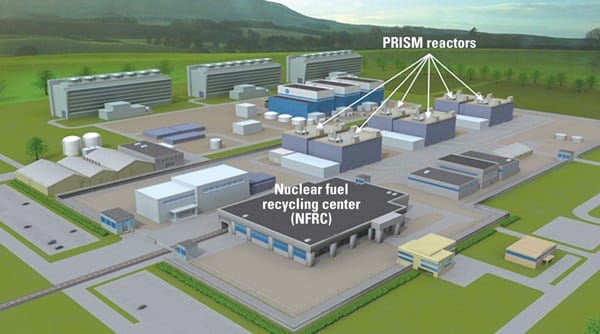

GE PRISM (1990s–Present): General Electric, a partner in the IFR program, took the Argonne design forward under the name PRISM (Power Reactor Innovative Small Module). PRISM is essentially the commercial descendant of the IFR concept – a modular sodium-cooled fast reactor with metal fuel and on-site fuel recycling. Each PRISM module is a 311 MWe pool-type SFR with inherent safety features (negative reactivity feedback, passive cooling, atmospheric-pressure operation). In the early 1990s, the Nuclear Regulatory Commission conducted a pre-licensing review and found “no obvious impediments to licensing the PRISM design”, a strong endorsement of its safety case. The full PRISM plant concept, called the Advanced Liquid Metal Reactor (ALMR), consisted of a Nuclear Fuel Recycling Center alongside multiple reactor modules to consume spent fuel and produce electricity. For example, one proposed PRISM plant would have six modules in three twin-reactor blocks powering a single large turbine, for a total of ~1,866 MWe output. Although PRISM was never built (due to changing national policy on fast reactors), GE Hitachi has continued to refine the design, pitching it for waste-burning and power projects (such as disposing of the UK’s plutonium stockpile). PRISM represents a bridge between the Argonne IFR research and the advanced reactor deployments we pursue today – keeping the IFR knowledge alive in a deployable design.

Natrium (2020s): In recent years, fast reactor development has been revived to meet clean energy goals, most prominently with TerraPower’s Natrium reactor. Natrium is a 345 MWe sodium-cooled fast reactor paired with an innovative molten salt energy storage system. Co-developed by TerraPower and GE Hitachi, it directly inherits design principles from EBR-II and PRISM (metal fuel, pool-type sodium cooling, passive safety), now augmented with grid-level storage. The U.S. Department of Energy selected Natrium for its Advanced Reactor Demonstration Program, and a full-scale demonstration plant is under construction near Kemmerer, Wyoming, at a retiring coal site. This first unit is slated for commercial operation in 2031. The Natrium demo project – estimated cost ~$4 billion with cost-sharing by DOE and private partners – aims to prove not only the reactor technology but also the novel salt storage in a real grid environment. Once operational, it will supply 345 MWe base load and can flex up to ~500 MWe using heat storage, enough peak power for about 400,000 homes. Natrium’s development signals a new generation of sodium fast reactors moving from paper designs to reality. Its success would effectively fulfill the IFR vision on a commercial scale: a safe, efficient fast reactor that closes the fuel cycle and complements renewables. The experience from Natrium will be directly applicable to Colorado Springs’ consideration of an IFR-based solution.

The IFR “Closed” Fuel Cycle

A defining feature of the IFR concept is its closed fuel cycle – the ability to continually reuse fuel and greatly reduce waste. In an IFR plant, the back end of today’s nuclear fuel cycle becomes the front end of tomorrow’s fuel supply. Key aspects of this closed cycle include:

Electrometallurgical Treatment (Pyroprocessing): Instead of treating “spent” fuel as waste, the IFR chemically reprocesses it on-site to recover remaining energy. The process is electrometallurgical, meaning it uses electrochemical methods in molten salts (at high temperature) to separate elements. Used metal fuel (or chopped oxide fuel that has been reduced to metal) is placed into a molten salt electrolyte. By applying an electric current, uranium and transuranic elements (plutonium, americium, etc.) are deposited on electrodes and separated from fission products. Unlike conventional PUREX reprocessing, which yields pure plutonium, the IFR’s pyroprocessing keeps all the transuranics mixed together with some uranium. The result is a recovered metal alloy that can be refabricated into new fuel for the reactor. This closed-loop recycling enables the IFR to consume ~96% of the original fuel material (including what would have been waste). For example, typical spent fuel from a light-water reactor is ~95% uranium and 1% transuranics that still contain enormous energy. The IFR process recycles these, only discarding the ~4% of truly depleted products. Pyroprocessing has been demonstrated at pilot scale – Argonne’s team successfully used it to recycle EBR-II fuel in the 1990s. A century-old alumina refining technology inspired this method, and importantly, it is designed to be proliferation-resistant: “the IFR’s pyroprocessing and electrorefining method is not capable of making plutonium pure enough for weapons.” Any would-be proliferator would have to undertake additional complex steps to get bomb-usable material, negating the covert appeal. This inherent barrier is a major strength of the IFR fuel cycle. Electrometallurgical treatment thus closes the loop, turning nuclear “waste” into fuel and greatly extending fuel resources.

Waste Streams (: The final high-level waste from an IFR is the concentrated fission products extracted during reprocessing. These are the isotopes that actually result from fission reactions – e.g. cesium, strontium, iodine, technetium – which cannot be burned further in the reactor. In pyroprocessing, most fission products remain in the molten salt bath or accumulate on the anode/cathode by-products. The IFR program developed a way to immobilize these fission products into stable waste forms. Specifically, the salt containing rare-earth fission products and halogens can be absorbed into a ceramic matrix (a vitrified glass-bonded zeolite), and metallic fission products can be incorporated into a stainless steel alloy ingot. These are the “waste forms for geologic storage” that were “developed and qualified” during IFR research. The ceramic and metal waste forms lock in the radioactive fission products and are designed to resist leaching or dispersal, making them suitable for disposal in a geological repository. Crucially, since nearly all long-lived actinides have been removed from this waste, its radiotoxicity drops to safe levels in a few hundred years. In fact, analyses showed that if >99% of actinides are recycled, the remaining waste’s toxicity falls below that of natural uranium ore in roughly 300 years. Thus the back-end waste is significantly less burdensome than current spent fuel: it no longer requires isolation for geological time spans. By volume, the waste is also much smaller – the fission products might amount to just 4% of the original fuel mass. This high-level waste would periodically be packaged and shipped off-site to a repository. But instead of thousands of tons of spent fuel, an IFR serving Colorado Springs would generate only a few tons per year of solidified fission product waste. In summary, the closed IFR cycle transforms the nature of nuclear waste: what leaves the site is minimal and short-lived compared to conventional reactors

On-Site Fuel Storage and Recycling: A hallmark of the IFR approach is that all fuel handling is done on-site in a secure, contained facility. Fresh fuel, spent fuel, and recycled fuel never have to travel over public roads after initial delivery. This is very different from today’s commercial reactors that accumulate spent fuel and eventually require off-site transport to storage or reprocessing facilities. In an IFR plant, spent fuel is transferred from the reactor to the adjacent recycling facility (likely co-located on the plant site) and immediately goes into the electrorefiner for recycling. The recovered actinides are then refabricated into new fuel elements on-site and go back into the reactor. This on-site loop means the IFR operates as a self-contained system – effectively a “nuclear battery” that is refueled from its own outputs. Argonne’s Dr. George Stanford described this vision: initially an IFR might take in some external fissile material (e.g. legacy plutonium or spent fuel from other reactors) to start up, but “it is consumed, with on-site recycling as needed. Only trace amounts ever come out.” Once running, the IFR would only need modest makeup feed (perhaps depleted uranium) to offset processing losses, on the order of 10 tons per year for a large plant. All of the fuel for decades of operation could be kept in vaults on-site. This not only improves security (less risk of theft or diversion in transport) but also streamlines operations – the utility isn’t dependent on a complex fuel supply chain. Colorado Springs Utilities would not need to procure fresh enriched uranium every 18 months as with current reactor. By storing an initial inventory of fuel and recycling it, the plant gains a high degree of energy independence. Moreover, keeping the fuel cycle on-site means the community doesn’t become a de facto radioactive waste shipping corridor. The IFR’s integrated design thereby localizes and minimizes the handling of nuclear materials. All that comes out are final waste packages for disposal, and even those are far less radioactive long-term than today’s spent fuel. This closed, on-site fuel cycle is what makes the IFR concept truly integral and distinguishes it as a forward-looking sustainable technology.

Molten Salt Thermal Energy Storage

One of the most innovative aspects of a Colorado Springs IFR plant is its molten salt thermal energy storage system. This is the same concept being demonstrated in TerraPower’s Natrium design – it allows a nuclear plant to flexibly store energy as heat and dispatch it when needed, much like a battery. The technology itself is borrowed from the solar power industry, where molten salt storage has been used successfully in concentrated solar power (CSP) plants. Key points about this storage system include:

“Solar Salt” as the Storage Medium: The IFR’s storage subsystem would use a nitrate-based molten salt commonly known as “solar salt” – typically a mixture of sodium nitrate (NaNO₃) and potassium nitrate (KNO₃). This salt melts at a few hundred degrees Celsius and is stable as a liquid up to around 550°C, making it well-suited to store the high-temperature heat from a sodium-cooled reactor. In fact, the operating temperature of a sodium fast reactor is an excellent match for the molten salt used in CSP plants. This means the nuclear heat can be transferred efficiently into the same salts already proven in solar facilities. Using solar salt leverages decades of industrial experience: it has been employed at commercial scale in plants like Nevada’s Crescent Dunes and Spain’s Gemasolar to store solar-generated heat. The salt is inexpensive, abundant, and non-flammable. It is kept in insulated tanks – one “hot” tank storing salt charged with heat, and one “cold” tank for cooler salt after it has delivered heat. When the reactor’s output exceeds current electricity demand, heat is diverted to the salt, raising its temperature (usually by ~100-200°C). To later recover the energy, the hot salt is flowed through a heat exchanger to produce steam for a turbine, cooling the salt which returns to the cold tank.

Scalability of Storage Capacity: A major advantage of thermal storage is its scalability. The amount of energy stored is mainly a function of the salt volume (and temperature delta); to increase storage capacity, one can simply add more salt or larger tanks. This is much more flexible than trying to scale a reactor’s power output directly. In practice, the Natrium design provides about 5.5 hours of full-power equivalent storage (enough to boost output from 345 MWe to 500 MWe for that duration). A single Natrium reactor has salt tanks that can store ~600 MWh worth of electrical energy as heat. For Colorado Springs, a four-unit IFR plant could bank a ~2.4 GWh worth of energy during low-demand periods (e.g. night or high wind output) and release it when needed – effectively time-shifting nuclear power output to complement renewables. As of 2025, 2.4 GWh of storage would be the third largest utility-scale battery system in the world. Such scale is crucial for integrating renewables: it can supply a city-sized load for hours. This decoupling of generation and delivery is revolutionary for nuclear energy. It means the IFR plant can function as both a steady baseload source and a peaking plant. Instead of building separate peaker plants or large battery farms, the city gets peaking capacity built into the nuclear station. In short, the IFR’s storage is modular and scalable, giving Colorado Springs a long-duration storage asset alongside generation.

High Efficiency and Low Cost: Molten salt thermal storage is a highly efficient way to store energy. The round-trip thermal efficiency (heat in to heat out) is typically on the order of 90–99%, since losses are only due to heat leakage from the insulated tanks (a well-designed tank loses just a few degrees per day). Essentially, very little of the reactor’s output is wasted when charging the salt – nearly all the heat can later be used to make steam and electricity. The main “inefficiency” is that the steam cycle itself (heat to electricity) has a finite efficiency (~40%), but that is true whether the heat comes straight from the reactor or from stored salt. There is no additional energy conversion step like in battery storage (which converts electricity to chemical energy and back, incurring losses both ways). Thus, from a system perspective, the IFR + salt storage is an efficient way to manage energy: you generate electricity when needed with minimal losses from when it was produced. Even more compelling is the cost: storing energy as heat in nitrate salts is dramatically cheaper per kWh than electrochemical batteries. Industry analyses have shown molten salt storage costs on the order of $20 per kWh-thermal, whereas lithium-ion battery farms cost around $300–$400 per kWh-electric for large installations. Even accounting for the lower thermal-to-electric conversion, that’s easily an order of magnitude difference in cost. One source notes molten salt tanks are “around 33 times less expensive than electric batteries” for each kWh of energy stored. This low cost is why virtually all CSP solar plants use molten salt for multi-hour storage instead of giant batteries. For Colorado Springs, it means the IFR’s integrated storage can provide buffering capacity at a fraction of the cost of achieving the same with battery projects. And unlike batteries that degrade over cycles, salt tanks can charge/discharge tens of thousands of times with minimal degradation. The salt does not “wear out” in normal use and the tanks can last for decades with proper maintenance. In summary, the IFR’s molten salt thermal storage is a proven, efficient, and cost-effective solution to make nuclear power responsive. It gives the city a way to bank clean energy and draw on it at will – effectively acting as a giant thermal battery that strengthens the overall resilience of our electricity supply.

What Would It Look Like?

An IFR-based power station in Colorado Springs would be a compact, campus-style facility with a distinct nuclear island and energy island. This proposal envisions 4 Natrium-class reactors, each ~345 MWe, housed at a single site. Collectively, these modules would supply about 1,380 MW of steady baseload power, with the ability to boost output to roughly 2,000 MW during peak periods by drawing on the thermal storage (providing over 5 hours of surge capacity). The plant could also decrease its output to 400 MW during periods of high renewable generation, e.g. cheap mid-day solar. The plant could ramp its electrical output from 20% to 100% in ~8 minutes. For perspective, this is enough to replace a large fossil power plant and serve a substantial portion of the region’s peak load. Grouping multiple small reactors is practical – GE Hitachi’s PRISM design, for example, was configured in 6-pack modules for ~1.8 GW total, showing that multi-unit fast reactor plants are feasible. The IFR plant’s four reactors would likely be deployed as twin units in two reactor buildings (for instance, two reactors per building, each pair driving a shared turbine set), to gain economies of scale. The nuclear island would be the high-security heart of the complex, containing the reactor buildings, primary sodium cooling systems, and the fuel cycle facilities. Each reactor is a pool-type vessel sitting below grade (for seismic stability and security) inside a containment structure. The reactor vessels and primary pumps would be housed in reinforced concrete silos with an inert gas cover to prevent sodium oxidation. Adjacent to the reactors, one would find the fuel recycling hot cell if full IFR fuel processing is implemented – a shielded facility where spent fuel is remotely processed and refabricated. This could be a relatively small building beside the reactor containment, designed for security and radiological protection.

Connected to each reactor’s primary system are intermediate heat exchangers that transfer heat from the sodium coolant to an intermediate sodium loop. These pipes would run to the energy island, which is the non-nuclear section of the plant. There, the sodium-to-salt heat exchangers transfer heat into the molten salt circuit. The energy island would feature large thermal storage tanks, likely two big cylindrical tanks (one “hot” salt, one “cold” salt) for each reactor module or perhaps a few larger shared tanks for the whole plant. In the rendering above, the energy island (left side) shows several round storage tanks – these would be prominent but not excessively tall (perhaps ~15–20 meters high). Also in the energy island are the steam generators and turbines. After charging the salt, when electricity is needed the hot salt is routed through steam generator heat exchangers to produce high-pressure steam. Thus, one would see a turbine hall with generators and transformers, similar to a conventional power plant, converting heat to electricity for the grid. From the outside, the energy island structures would resemble an industrial facility – tanks, heat exchangers, a turbine building – but notably absent are large cooling towers. Air-cooling is far more likely given Colorado’s water limitations. The Natrium design’s use of simpler, low-pressure components means smaller buildings. TerraPower notes the design uses “80% less nuclear-grade concrete” per MW than today’s LWR plants, so the nuclear island would be relatively compact. Visually, the plant might appear as a cluster of low-rise robust concrete buildings (for the reactors and fuel facility) on one side, and several cylindrical salt tanks and a turbine building on the other side. All would be within a secured perimeter with buffer distance.

The entire complex could fit on a site such as Colorado Springs Utilities’ Clear Springs] Ranch property. This site already has the Front Range combined-cycle plant (480 MW), the Ray Nixon coal plant (185 MW) and natural gas “peakers” (30 MW). The Nixon plant is scheduled for retirement in 2029, a critical step in achieving Colorado’s ambitious 2030 emissions targets. Also of note: the Front Range plant uses Air Cooled Condensers (ACC) to reduce water usage of the steam turbine. The ACC is the large elevated structure in the picture.

Being near existing transmission lines and water sources (for steam cycle cooling) is advantageous. The reactor units themselves require only a small fraction of the land – most of the site would be for support facilities, switchyards, and buffer zones. We can expect to see a control building where operators monitor the reactors and storage system, a maintenance building, and possibly a training center on site. From a distance, an IFR plant would not have the huge cooling tower plumes of a coal plant; it might have mechanical draft cooling or dry cooling for the condensers, which are much less conspicuous (the rendering shows row of cooler units). Additionally, because the reactor operates at atmospheric pressure, there is no massive containment dome required – reactor buildings would be more modest in profile. In summary, the IFR plant would look like a modern, clean industrial installation: secure and high-tech, but far from the sprawling, smokestack-laden fossil plants of the past. Its most distinctive visual elements would be the salt storage tanks, signifying the advanced storage capability on site. This facility, integrating four reactors with thermal storage, would set a powerful example of the “nuclear + storage” model – essentially a next-generation power station capable of delivering both steady and peaking power as needed for Colorado Springs.

Financial Estimates

Implementing an IFR-based energy solution is a major infrastructure project, and it is important to consider the economics realistically. While advanced nuclear plants have high upfront costs, they also provide very long-term value (decades of electricity, capacity, and fuel savings). Here are rough financial projections for a Colorado Springs IFR and the expected timeline:

Capital Cost: Initial estimates put the cost of a first-of-a-kind Natrium unit (345 MW with storage) at about $4 billion. This includes significant one-time expenses in design, licensing, and establishing supply chains. For a four-unit, ~1.4 GW IFR plant, the capital cost would not simply be 4×$4B = $16 billion; we anticipate some economies of scale. Shared infrastructure (the site, security, control systems, salt storage, turbines, and grid interconnects) means additional units cost less than the first. A very rough order-of-magnitude estimate might be on the order of $12 –$15 billion total for the four-unit complex. This figure is competitive when compared to other options: for example, a recent estimate for a 600 MW small modular LWR plant came out to $12.9 billion, and Xcel Energy found that cost prohibitive. In contrast, the IFR’s simpler modular design and the ability to build much of the plant off-site can help contain costs. TerraPower reports design features that “reduce complexity, cost, and construction time” – e.g. separating the nuclear and non-nuclear buildings (so they can be built in parallel) and using less specialized concrete and steel. Over an 80-year lifespan, a $12–16B investment becomes very cost-effective – the plant would produce on the order of a million megawatt-hours per year, making the levelized cost of electricity potentially quite reasonable when fuel and O&M costs are low (IFR fuel is inexpensive, coming from waste). Still, financing such a project would require creative approaches: possibly a consortium of municipal utilities, federal loans or loan guarantees, and rate-based recovery spread over many years. The key is that while the sticker price is high, the value delivered (reliable carbon-free power + storage for much of a century) is correspondingly high, and there are mechanisms to mitigate the upfront burden.

Construction Schedule: Advanced nuclear projects are typically expected to take around 5–7 years from ground-breaking to operation for a single unit. The Natrium demonstration is planned on a ~4-year construction timeline (2026 start to 2031 operation), including NRC permitting. Note: Kemmerer Station 1 has started construction of non-nuclear sections of the plant. Nuclear construction is expected to start after the construction permit is issued in ~ 2H 2026. The eventual target time for completion of a single unit is 3 years. A four-unit IFR plant might be built in phases, with the first reactor coming online while the later ones are still in construction. Thanks to the modular nature, a staggered approach could allow the first module’s revenue to support later builds. If site work and regulatory approval are completed ASAP, the first reactor could potentially be operational by ~2033, with all four reactors and the full storage system in service by ~2035. This aligns with the city’s planning horizon for replacing aging infrastructure and meeting climate goals. Notably, subsequent units should build faster than the first as lessons are applied – the later reactors might be completed in closer to 3–4 years each, possibly with overlapping construction crews. The IFR’s design simplifications (factory-fabricated components, no large pressure vessel forge delays, etc.) aim to compress construction schedules compared to conventional nuclear. TerraPower’s approach of separating the “nuclear island” and “energy island” means the non-nuclear structures (salt tanks, turbine hall) can be built without waiting for nuclear regulatory steps, accelerating the timeline. Regulatory timelines should also be considered: Springs Utilities would need NRC licensing for the reactor and a fuel cycle facility. Using the Natrium as a reference design would streamline this, as the NRC would already have familiarity (the Natrium demo will be licensed). Still, we should allocate a few years for design certification and combined license processes. All told, a reasonable expectation is that an IFR plant could be producing power within about 8 years from project go-ahead. This is a long lead time, but comparable to other major power projects (for example, large hydro dams or first-of-kind CCS plants) and the longevity of the asset (80 years) more than justifies the initial patience.

Operating Costs and Fuel: Day-to-day operating costs of an IFR plant would include staffing (operators, engineers, security), maintenance, and the fuel cycle operations. Traditional nuclear plants have relatively high fixed O&M costs; however, an IFR might benefit from simplifications like smaller staff (due to advanced safety automation) and lower fuel costs. The IFR fuel essentially comes from already-mined material – either depleted uranium (DU) or spent fuel from other plants – which could be very cheap or even viewed as waste liability turned asset. There may be costs in conditioning that material for use (e.g. converting DU oxide to metal, or fabricating driver fuel), but these are incurred mostly in the initial core loads. Once running, the IFR consumes its own recycled fuel, so ongoing fuel expenditures are minimal (maybe the cost of processing and some makeup DU). By eliminating enrichment (a major cost for current nuclear fuel), the IFR saves a lot; Argonne estimated the IFR fuel cycle could be economically competitive, as fuel recycling cost would be balanced by the value of the energy recovered. Waste disposal costs would also be much lower in volume (though we must still plan for final disposal of fission product waste). Springs Utilities should support consent-based siting in choosing a final waste reposity. The recent selection of Ignance, Ontario and the Wabigoon Lake Ojibway tribe in Canada should be heralded for their success in consent-based siting. The city and tribe fought for 15 years to get the nuclear repository, for the long-term jobs it would bring. Additionally, the IFR plant would earn revenue not just from energy sales but potentially from capacity services and load-following ancillary services, thanks to its storage. It could provide spinning reserve, frequency control, and peak capacity, which in future high-renewable grids can command premium payments. All these factors would feed into the economic analysis. A full lifecycle cost analysis over 60–80 years (as recommended by the Utilities Policy Advisory Committee) will likely show that while initial capital is the main investment, the long-term cost of power from an IFR plant can be very competitive with other dispatchable clean resources, especially if carbon costs or methane price volatility are taken into account.

In conclusion on finances, an IFR for Colorado Springs is a big-ticket project upfront, but it would also be a strategic generational investment. It would fix the cost of electricity for decades in a narrow band, immune to fuel price swings, and with assured capacity. Springs Utilities should continue to refine these estimates and compare them to alternatives (like light-water SMRs or renewables plus storage) as we move forward towards the EIRP process. Fortunately, early indicators (from Natrium and other SMR projects) suggest advanced nuclear is becoming more financially viable, particularly with federal support and innovative financing. The goal will be to minimize risk to ratepayers while securing the immense benefits of this technology.

Risks

Every energy technology comes with risks and challenges that must be acknowledged and managed. The IFR proposal is no exception. As a responsible engineer, I remain optimistic about IFR technology while being candid about its risks and open to evaluating alternatives. Two primary risk area identified are the fuel recycling aspect and the novel integration of sodium and salt in the system:

Reprocessing & Proliferation Concerns: The IFR’s closed fuel cycle, which involves on-site reprocessing of fuel, could raise concerns regarding nuclear proliferation and operational complexity. Traditional reprocessing (PUREX) has a reputation for producing pure plutonium which can be diverted to weapons, and this is a political and public perception hurdle. The IFR’s pyroprocessing, by design, does not separate pure plutonium – the plutonium stays mixed with other actinides and uranium, and is quite unusable for weapons without further chemical processing. This intrinsic safeguard is a strong point in IFR’s favor. Nonetheless, any form of reprocessing triggers stricter regulatory scrutiny and requires robust safeguards to ensure no materials are misused. We will need to work closely with the NRC, DOE, and international bodies to demonstrate that an IFR fuel cycle facility can meet the highest non-proliferation standards. There’s also technical risk in scaling up pyroprocessing to commercial throughput. While Argonne ran a successful demonstration with EBR-II fuel, doing this at the scale of dozens of tons per year is a step up. Challenges include remote handling of highly radioactive fuel in hot cells, maintaining the electrorefiner chemistry over long periods, and managing the process waste streams. These are engineering issues that will require further R&D and probably a pilot plant (the Natrium demo will not include fuel recycling initially – it will use fresh enriched metal fuel). Therefore, one strategy could be a phased implementation: initially operate the Colorado Springs IFR in an “open cycle” mode (store the spent fuel safely on-site) while the recycling technology is perfected and licensed, then add the recycling capability later. This way, the reactor deployment won’t be delayed waiting for the full closed cycle. Another aspect is public acceptance – the term “reprocessing” may alarm some, given past controversies. Springs Utilities needs a strong public education effort to explain that IFR fuel recycling is fundamentally different and “cannot produce weapons-usable plutonium”, and that it greatly reduces waste. By being transparent and inviting input from the community and experts, Springs Utilities can address these concerns. In summary, the fuel cycle risk is real but manageable: it requires careful regulatory planning, possibly a gradual approach, and clear communication that IFR technology changes the game on proliferation and waste. Springs Utilities should also evaluate fallback options (like partnering with a national lab to take the material if on-site processing faced issues). The bottom line is that the IFR’s benefits in waste reduction and fuel security come with the responsibility to implement reprocessing safely – a challenge we should be prepared to meet, but one that rightly demands diligence.

Sodium & Salt Integration (Chemical Safety): The IFR design introduces an innovative coupling of two fluids: liquid sodium in the intermediate (non-radioactive) sodium loop and molten salt in the storage loop. Each of these has been used separately in industry (sodium in past fast reactors, salt in solar plants), but putting them together is new and comes with some risk. Sodium metal is famously reactive – it burns if exposed to air and can explode if contacting water. Decades of operating experience (EBR-II, FFTF, and others) show that sodium systems can be managed safely with proper engineering and inert cover gas. However, there have been incidents: e.g., the Monju fast reactor in Japan had a sodium leak and fire in 1995 when a thermometer broke. That fire caused no injuries or public harm and was contained, but it became a public relations fiasco that kept Monju offline for years and led to the plant’s early retirement. This teaches us that even a minor sodium event can have outsized consequences if not handled with transparency and rigor. In the proposed IFR plant, the primary (slightly radioactive) sodium would be sealed inside robust pipes and vessels with continuous monitoring for leaks (as EBR-II had a leak detection system in a guard vessel). Any leak would drain into catch basins and be blanketed by inert gas to prevent combustion. New to Natrium/IFR is the sodium-to-salt heat exchanger: here, if a leak occurred, sodium and nitrate salt could mix. What happens then? Chemically, molten nitrate salt can oxidize sodium; this would likely result in a vigorous reaction (potentially producing sodium oxide, sodium nitrite, and heat, possibly releasing some nitrogen oxides gas). It would not be as rapid or gas-generating as a sodium-water reaction (no steam or hydrogen to explode), but it could still cause localized pressure or damage the heat exchanger. TerraPower’s design mitigates this by having an intermediate sodium loop and double-walled heat exchanger tubes, so that any breach would ideally be caught in a gap before sodium contacts salt. In fact, one motivation for using salt was to avoid the far more dangerous sodium-water interaction in steam generators – traditional SFRs have to isolate sodium from water/steam at all costs. By moving to a sodium/salt interface, they assert that “this reduces the risk relative to prior [sodium-water] designs.” Springs Utilities must scrutinize this claim with independent experts, but it stands to reason that a non-combustible salt is a safer intermediate fluid than water. Still, the sodium/salt interaction is a new hazard to analyze. Springs Utilities must ensure the design includes properly engineered features. Additionally, thermal stresses must be managed – both sodium and salt expand when heated, so the system needs to accommodate temperature transients without cracking pipes or welds. On the operational side, sodium and salt each require different handling: sodium must be kept air-free (in argon cover), and salt must be kept dry (to avoid corrosion). The plant will need robust chemistry control programs. These complexities will demand a well-trained staff and perhaps new regulatory standards for a hybrid system. The good news is that the fundamental safety of the reactor itself remains excellent – the reactor is still passively safe and low-pressure. Any sodium or salt leak, while undesirable, does not pose the kind of public radiation release risk that, say, a loss-of-coolant accident in a water reactor could. The radioactive materials are inside the reactor vessel and would stay there (recall that even Monju’s leak was in a secondary loop, involving no radiation). So the risks here are mainly industrial and chemical. Proper engineering can virtually eliminate the chance of a major fire or explosion, and containment and safety systems will manage any incidents that do occur. Springs Utilities’ plans must include in-depth safety analyses of the salt storage system, drawing on data from the ongoing Natrium prototype. Springs Utilities must also have emergency response procedures specifically for sodium fires (local fire departments would be briefed and equipped for a sodium incident, which involves special dry extinguishers, etc.). Overall, while the sodium/salt interface adds a novel risk, it is not a show-stopper. It is a trade-off that appears to improve overall plant safety by removing water/steam from the nuclear island. Springs Utilities must actively manage this risk through design, testing, and training, ensuring that the IFR plant operates with the highest level of safety in all its systems.

In summary, the IFR proposal for Colorado Springs offers a bold but well-founded path to a sustainable energy future: decades of clean power, built-in storage to firm up renewables, radical reduction of nuclear waste, and freedom from fuel mining. The history of sodium fast reactors and the successes of EBR-II and IFR research give us confidence that this technology can deliver as promised. Of course, due diligence is required:

Springs Utilities should continue to study the economics and safety and acknowledge the challenges of deploying a first-of-a-kind system.

Springs Utilities should also remain open-minded: as Springs Utilities make decisions, Springs Utilities should compare the IFR approach with alternative solutions such as advanced light-water SMRs or other emerging technologies.

The goal is to ensure Colorado Springs invests in the best long-term solution for reliable, affordable, and clean energy.

At present, the Integral Fast Reactor concept stands out as a compelling option that addresses multiple needs at once. By leveraging a proven fast reactor design (modernized for the 21st century) and combining it with innovative storage, we can position our city as a leader in the clean energy transition.

An “IFR for Colorado Springs” would not only power our homes and businesses with zero-carbon energy, but also turn our existing nuclear waste liabilities into assets, and pave the way for an energy-secure future for generations to come. It is a visionary step – one that embodies both pragmatism and long-term thinking. Let’s continue to evaluate this proposal rigorously, engage with our community and experts, and move toward a decision that will bring lasting benefits to Colorado Springs. The promise of the IFR is plentiful energy, and with careful stewardship, it may well be the cornerstone of our city’s energy strategy as we strive for a sustainable and prosperous future.

Sources:

Plentiful Energy: https://www.thesciencecouncil.com/pdfs/PlentifulEnergy.pdf

The Integral Fast Reactor (IFR): An Optimized Source for Global Energy Needs: http://large.stanford.edu/courses/2015/ph241/jones1/docs/179693_replacement.pdf

What is the IFR : https://www.ne.anl.gov/About/reactors/ifr/What%20Is%20the%20IFR.25.pdf ‘

The EBR-II Inherent Shutdown and Heat Removal Tests - A Survey of Test Results: https://www.osti.gov/servlets/purl/5913652

PRISM: A COMPETITIVE SMALL MODULAR SODIUM-COOLED REACTOR:

https://www.gevernova.com/content/dam/gevernova-nuclear/global/en_us/documents/prism-technical-paper.pdfThe Natrium Technology Sodium Fast Reactor & Integrated Energy Storage: https://www.nuclearaustralia.org.au/wp-content/uploads/2023/10/P06_Navin_ANA2023.pdf

December 2024 UPAC Meeting Materials: https://www.csu.org/hubfs/39606065/UPAC%20Meeting%20Materials%2012-4-25-1.pdf?hsLang=en

Disclaimer: All recommendations in this essay reflect the author’s views as a private citizen and not as a representative of the Utilities Policy Advisory Committee (UPAC) or Colorado Springs Utilities. The ideas presented here are intended to inform public discourse under the author’s First Amendment rights, and should not be interpreted as official UPAC positions.