SMRs for Colorado Springs

A broad comparison of nuclear options for a city at 6,000 feet elevation

Key Takeaways

Small modular reactors are claimed to be faster to build and safer to operate than existing reactors, but that has yet to be demonstrated.

There are several reactor designs under development, and some in various stages of construction.

These reactors do build on thousands of reactor-years of operational experience in light-water reactor (LWRs)s.

All major SMRs follow the same “enriched uranium, once through” fuel cycle as all nuclear power reactors currently active in the US.

They share the same current pitfalls as previous generation reactors in terms of waste generation. The generation of waste will continue to be a topic of concern for many residents.

Any nuclear generation in Colorado Springs, Colorado, and the western US in general must be concerned about water consumption. Reducing the water impact of nuclear power will be critical to adoption in these climates. Solving the “water energy nexus” in general is a key challenge for our generation.

Any nuclear project would likely cost between $10 and $20 billion dollars. These are large capital expenditures with correspondingly long capital lifetimes (60 to 80 years).

Regulatory Landscape in Colorado

Colorado has recently opened the door for nuclear energy as part of its clean energy goals. In 2025, the state legislature passed House Bill 25-1040 and was signed by Gov. Jared Polis. This bill explicitly added nuclear energy to Colorado’s statutory definition of “clean energy” for purposes of meeting carbon-reduction targets. Source Notably, the law carves out an exception so that nuclear isn’t treated as “clean” for certain property tax valuations, but for energy planning it is now on par with other carbon-free resources. Source This legislative change signals that nuclear power – including next-generation small modular reactors (SMRs) – can be considered in utility resource plans alongside renewables.

Locally, Colorado Springs Utilities (CSU or “Springs Utilities”) has begun evaluating nuclear energy in its Integrated Resource Plan process. In 2024, the CSU Utilities Policy Advisory Committee (UPAC) – a volunteer citizen advisory group – was tasked with studying the feasibility of SMRs for the city. UPAC’s study examined current SMR technologies, regulatory and permitting issues, water usage, environmental factors, and potential costs of adding nuclear power to the Colorado Springs portfolio(Source). By early 2025, UPAC recommended that CSU seriously consider an SMR in future planning. (Source). The Colorado Springs Utilities Board (which is the City Council wearing a “different hat”) reviewed UPAC’s findings in February 2025 and unanimously approved a set of proactive nuclear recommendations. Source Source These included: periodically revisiting nuclear options in each IRP cycle, pursuing an early site permit from the Nuclear Regulatory Commission (NRC) for a possible SMR site in the Colorado Springs area, and increasing public education and engagement around SMR technology. Source In short, both state policy and local utility interest have aligned to make SMRs a timely topic for Colorado Springs’ future energy plans.

Disclaimer: The author serves as a non-voting, alternate member of UPAC. This article is representative of the author’s views as a private citizen of Colorado Springs and Springs Utilities rate-payer. It is NOT representative of the views of Colorado Springs Utilities or the Utility Policy Advisory Committee.

Key SMR Designs

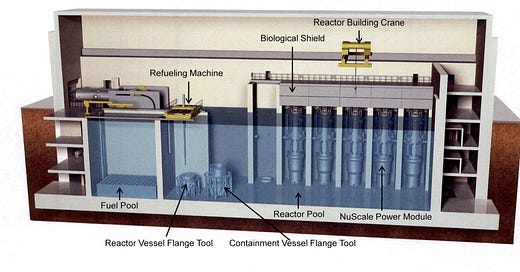

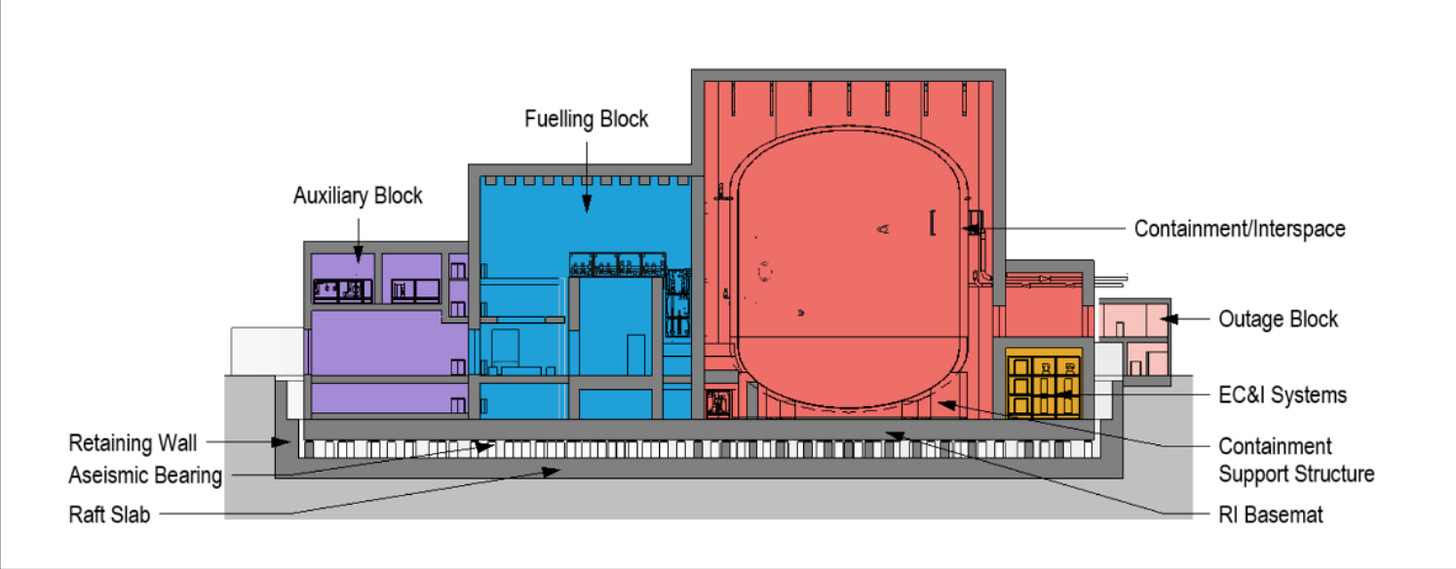

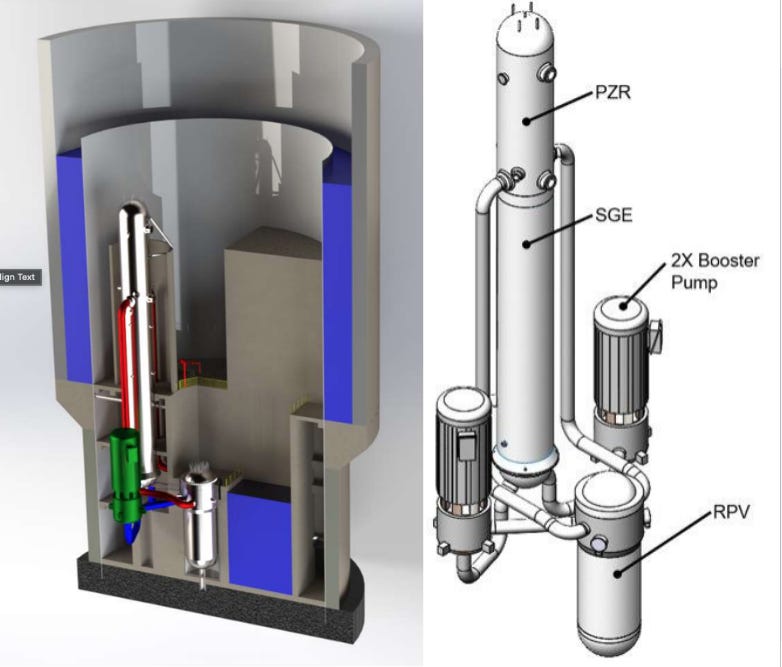

NuScale VOYGR-6/12 (U.S.) – A modular pressurized-water reactor (PWR) design featuring natural circulation cooling and a high level of passive safety. Each NuScale Power Module produces about 77 MWe (250 MWt) Source. A VOYGR plant can house up to 12 modules for ~924 MWe total. NuScale’s design is fully modular: the reactor vessel, steam generator, and containment are integrated into a single unit immersed in a water-filled pool. This provides indefinite cooling without external power or additional water in emergencies. NuScale’s 50 MWe version became the first SMR design certified by the U.S. NRC in 2020. and an uprated 77 MWe design (VOYGR) is now under NRC review. Source Source. The first SMR major SMR project in the US, the Carbon Free Power Project by UAMPs in Utah was cancelled after prices rose significantly.

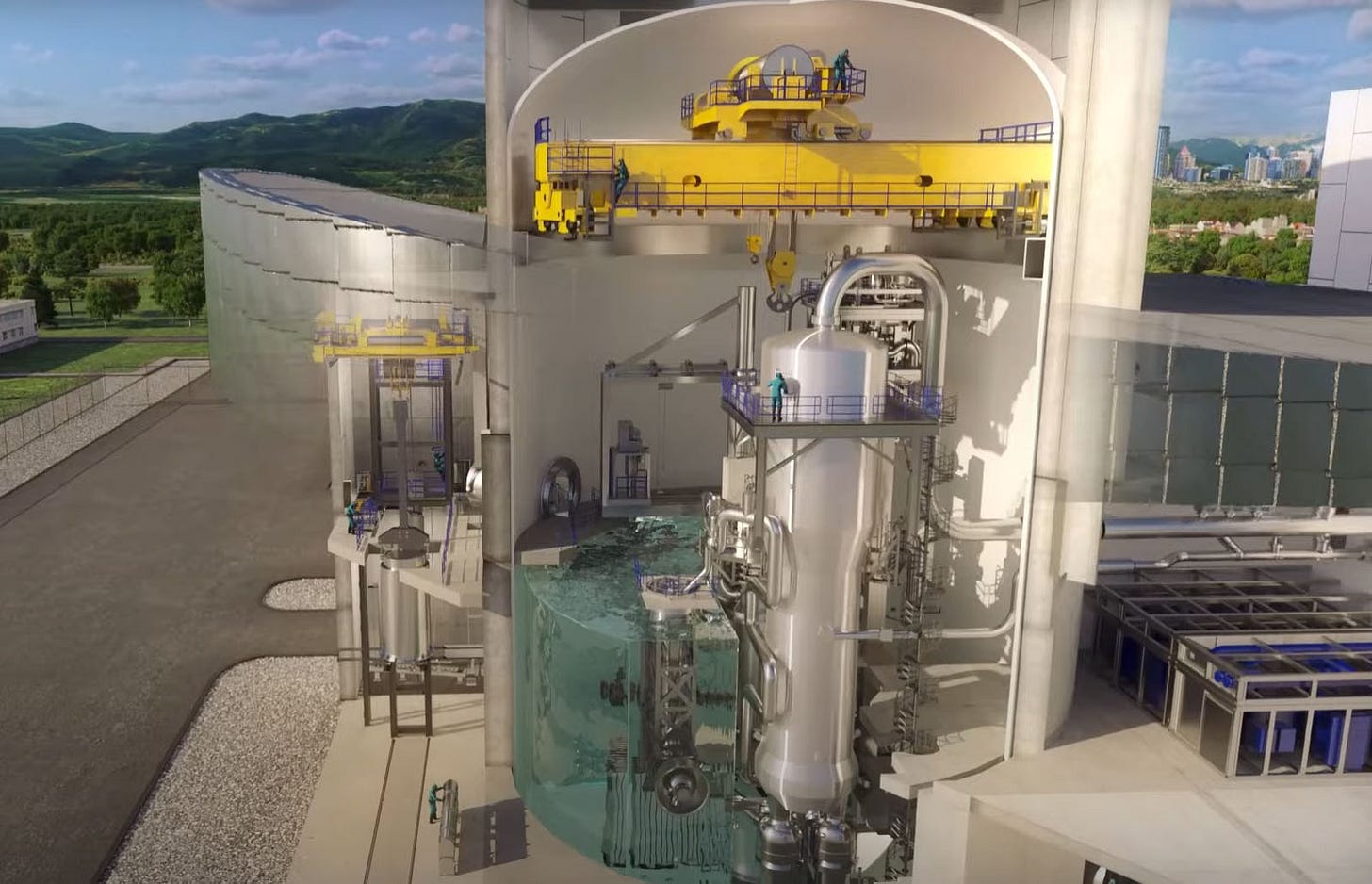

GE Hitachi BWRX-300 (U.S./Canada) – A 300 MWe light-water boiling water reactor (BWR) that builds on GE’s long operating experience with BWRs. The BWRX-300 is derived from the Generation III+ ESBWR design (which was certified by the NRC) but with simplifications to reduce cost and construction time. It uses natural circulation cooling in the reactor vessel (eliminating large recirculation pumps) and passive safety systems like gravity-driven cooling and isolation condensers for emergency core cooling. GE Hitachi aims for this design to be cost-competitive by leveraging standard fuel, components, and an existing supply chain. The first unit is slated for deployment at Ontario’s Darlington site in Canada by 2028, with a total of 4 under contract. In the U.S., the Tennessee Valley Authority is pursuing a Part 50 construction permit to build a BWRX-300 at its Clinch River site. Source.

Holtec SMR-300 (U.S.) – A 300 MWe PWR design evolved from Holtec’s earlier SMR-160. Holtec recently doubled the output of its design (from 160 to 300 MWe) to improve economicsSource Source. The SMR-300 uses conventional PWR fuel (low-enriched uranium) and a two-loop primary system. It employs “walk-away” passive safety, meaning it can achieve safe shutdown and cooling with no operator action or external power, similar in philosophy to NuScale. Initially conceived with natural circulation, the 300 MWe version may incorporate small pumps in the primary loop to ensure adequate flow at the higher power, though the core and safety approach remain fundamentally similar to existing PWRs. Source The entire reactor system is compact and largely installed below grade for security and radiation shielding. Holtec is in pre-licensing engagement with the NRC Source and has also begun a generic design assessment in the UK Source, aiming to deploy its first SMR-300s by the early 2030s (potentially at the former Palisades nuclear site in Michigan).

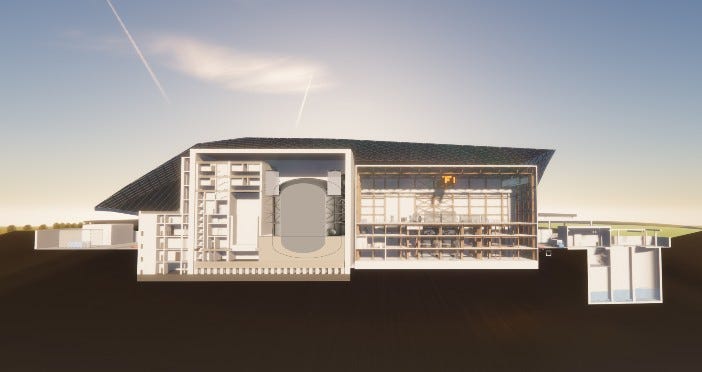

Westinghouse AP300 (U.S.) – A 300 MWe PWR announced in 2023 as a scaled-down version of Westinghouse’s proven AP1000 reactor. The AP300 design leverages the same passive safety systems as AP1000 – such as passive cooling via gravity-fed water and natural circulation – but with a smaller core and containment. By “copying and pasting” the AP1000’s technology at one-quarter scale, Westinghouse intends to minimize new engineering risk. Source The AP300 uses standard 17x17 PWR fuel and operates at similar pressures and temperatures as large PWRs, but with a single reactor coolant loop (or two loops) instead of the AP1000’s two larger loops. This reactor targets deployment in the early 2030s and is in pre-application with NRC. As of 2025, the design is not yet certified; Westinghouse will likely pursue a Part 52 design certification similar to what it did for AP1000.

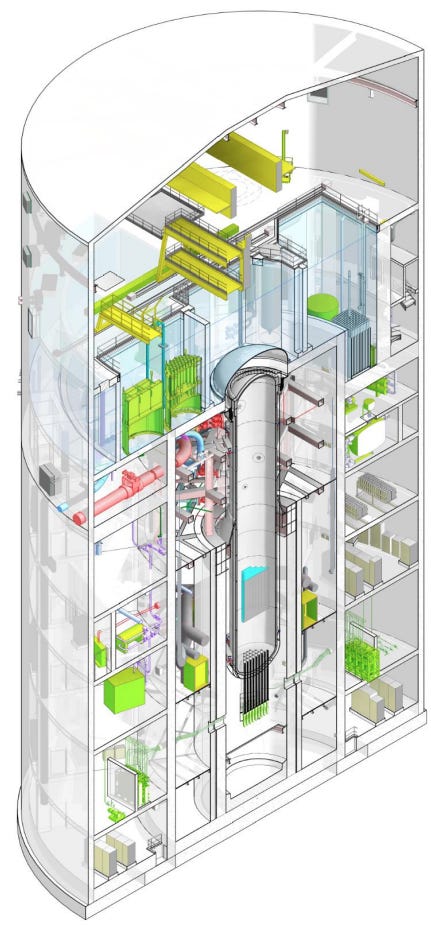

Rolls-Royce SMR (UK) – A larger SMR at 470 MWe, being developed with UK government support. Rolls-Royce’s design is a 3-loop PWR with active pumps (three primary coolant pumps and steam generators) and additional passive safety features Source. It uses standard nuclear fuel (<5% enriched UO₂) and aims for a high thermal efficiency of about 35%, which is slightly better than typical large PWRs (~32–34%). A major promise of the Rolls-Royce SMR is factory fabrication: approximately 80% of the plant is to be built as modules in a factory and then shipped to site for assembly. Source This approach is expected to enable a rapid construction time of about 3–4 years on site for each unit (after first-of-a-kind) Source. Economies of series production are central to Rolls-Royce’s plan – once in full production, a 470 MWe unit is projected to cost around £1.8 billion (≈$2.2 billion) Source, or roughly £3.3 billion per GW, which is much cheaper per capacity than today’s large nuclear plants in the UK. The design is currently undergoing UK regulatory review and has not yet been submitted to the NRC.

These five designs share the goal of safer, more flexible nuclear power in a smaller package. All are water-cooled reactors with familiar light-water fuel cycles, but they each approach modular construction and cost reduction a bit differently. Below we compare them across several key factors relevant to Colorado Springs.

Why not the AP1000?

While the AP1000 has often served as the “reference” large light water reactor (LWR) in nuclear comparisons, it is unlikely to be a good fit for Colorado Springs. The most fundamental limitation is its current incompatibility with air-cooling. A 2009 feasibility study by the U.S. Nuclear Regulatory Commission concluded that adapting the AP1000 to use dry cooling would require extensive redesign of the turbine building, including the addition of 30-foot wide elevated steam ducts and significant alterations to the secondary side of the plant. These changes would not only add complexity and cost but also delay construction. Given Colorado Springs’ semi-arid climate and constrained water supplies, any nuclear project must be compatible with dry or hybrid cooling options from the start—a standard AP1000 simply isn’t.

Beyond water concerns, the AP1000’s large size creates additional challenges. Large reactors are capital-intensive and typically take 8–10 years to construct. While their “overnight” cost per kilowatt may seem competitive on paper, that figure doesn’t capture the full financial burden. Long construction timelines lead to significant interest during construction (IDC), meaning utilities and ratepayers bear higher financing costs before a single electron is generated. Additionally, large reactors have slower ramp rates and are generally less flexible in load-following—an increasingly important requirement in grids with growing shares of wind and solar. These limitations make the AP1000 ill-suited to serve as a dispatchable partner for renewables in a flexible, water-constrained system like Colorado Springs.

Technical Comparison of SMRs

NuScale VOYGR-77

Strengths:

Fully modular, integral reactor design enables factory fabrication and modular site deployment.

50 MW version is the only SMR with NRC Part 52 certification

No primary (radioactive) loop piping - a major accomplishment

Operates using natural convection; no reactor coolant pumps.

Large water pool acts as a passive heat sink, supporting indefinite cooling without external power.

Extremely low operator dose due to remote handling and water shielding.

Offers flexible phased construction: modules can be added over time and operated independently.

Weaknesses:

High capital cost: FOAK project costs rose to ~$20,000/kW.

Significant excavation and civil work required for below-grade pool.

77 MWe version not yet certified by the NRC (as of 2025).

Slightly lower thermal efficiency (~30%), leading to higher cooling load and more fuel waste per MWh.

GE Hitachi BWRX-300

Strengths:

Builds on proven BWR/ESBWR platform, simplifying NRC review.

Compact design with natural circulation, passive cooling, and reduced active components.

Innovative SteelBricks™ modular containment enables faster construction.

High thermal efficiency (~32%) and robust load-following.

Competitive capital cost projections (~$4,000–$7,000/kW).

Weaknesses:

Boiling water means radioactive steam is sent to the turbine.

Historically higher operator dose rates for BWRs.

Limited thermal margin may limit dry cooling effectiveness, particularly in hot months.

NRC licensing under Part 50 still underway (no Part 52 certification yet).

Holtec SMR-300

Strengths:

Vertically integrated supplier; Holtec manufactures key components and spent fuel storage systems.

Compact PWR design with passive safety and low seismic profile.

Advertises fixed-price turnkey contracts.

Designed to pair with Holtec dry cooling and thermal storage systems (HI-THERM).

May be suitable for brownfield sites and air-cooled deployment.

Weaknesses:

New design; limited published technical documentation.

Formerly based on SMR-160, which was a different size and cooling profile.

No NRC certification or construction permit yet; pre-licensing only.

"Green Boiler" terminology is ambiguous and poorly defined.

Westinghouse AP300

Strengths:

Scaled-down AP1000: leverages licensed, proven safety systems.

Passive safety with gravity-fed emergency cooling.

Simplified PWR design likely to facilitate regulatory review.

Suitable for Part 52 certification path based on AP1000 precedent.

Weaknesses:

Larger reactor vessel and steam system may complicate modularity.

Thermal efficiency on the lower end (~28%).

Not yet submitted for NRC design certification.

Competes internally with large-scale AP1000 deployments for resources and attention.

Rolls-Royce UK SMR

Strengths:

Highest power density, ~470 MWe in a compact footprint.

Factory-based modular construction: up to 80% fabricated off-site.

Projected fast build time (~4 years) after FOAK.

High thermal efficiency (~35%) reduces cooling requirements.

Potential for early U.S. partnership or licensing.

Weaknesses:

Not engaged with NRC as of 2025; no U.S. licensing.

UK design assumptions may not align with U.S. codes and climate.

Larger size may pose challenges for dry cooling in arid environments.

Deployment path in the U.S. still undefined.

Financial Comparison of SMRs

These plant configurations were designed to be roughly comprable. Of course, you could increase the number of SMRs to match a dual-unit AP1000 with a correspeonding increase in total cost. I choose 4x SMRs because I consider than the “minimum viable” number of reactors to achieve economies of scale. With less reactors, you run the risk of overhead costs decreasing economics.

On personal judgement, the NuScale overnight cost seems abnormaly high and the Rolls-Royce overnight cost seems abnormaly low. Also, note that these are publicly avilable estimates and could change dramatically when it comes to actual answers to RFI/RFPs.

AP1000: Estimates based on MIT's 2024 projection for next-generation units.Massachusetts Institute of Technology

NuScale: Costs derived from the Carbon Free Power Project's latest estimates.

BWRX-300: Figures from Tennessee Valley Authority's Integrated Resource Plan.LinkedIn

Holtec SMR-300 and AP300: Estimates based on industry analyses and comparisons.

Rolls-Royce SMR: Cost per kW based on UK government estimates for fifth-of-a-kind units. LinkedIn

SMR Cooling and Water Usage in Colorado

Colorado Springs Utilities manages a water supply system with a total capacity of approximately 200,000 acre-feet, drawing on a combination of surface and groundwater sources, including extensive infrastructure that moves water across the Continental Divide. Annual municipal water use averages around 70,000 acre-feet, with the system capable of sustainably supplying up to 90,000 acre-feet per year. This buffer reflects decades of investment and planning, but it also underscores the importance of careful stewardship of water—our most critical and limited resource. Any nuclear project proposed for Colorado Springs must fully account for these constraints. While SMRs offer promising flexibility, designs that rely on traditional wet cooling may consume thousands of acre-feet annually. For a city in a semi-arid region, any future nuclear deployment must prioritize water-efficient designs, such as air cooling or the use of reclaimed non-potable water, to align with long-term sustainability goals.

Observations

Air-cooled systems cut water use by ~90% but come with tradeoffs: larger radiators, higher cost, lower thermodynamic efficiency.

The AP1000, using traditional wet cooling, requires more than 10× the water of the others.

These estimates assume modern dry air condensers with hybrid systems in arid regions.

Note: Thermal power is calculated as Electric Output divided by Thermal Efficiency. Heat rejected is the difference between Thermal Power and Electric Output.

These calculations provide a clearer picture of the cooling requirements for each reactor configuration, which is essential for planning in regions like Colorado Springs where water resources may be limited.

Nuclear Waste for LWRs

A common question is: Will SMRs produce more or less nuclear waste than existing reactors? Since all these candidate designs use traditional LEU (low-enriched uranium) fuel and operate on a “once-through” fuel cycle, the type of waste is essentially the same as from current light-water reactors – primarily spent nuclear fuel (SNF) assemblies that contain the used uranium fuel and fission products. There are some nuances in waste volume and characteristics, but generally SMRs produce comparable spent fuel per unit of electricity as large reactors. Source

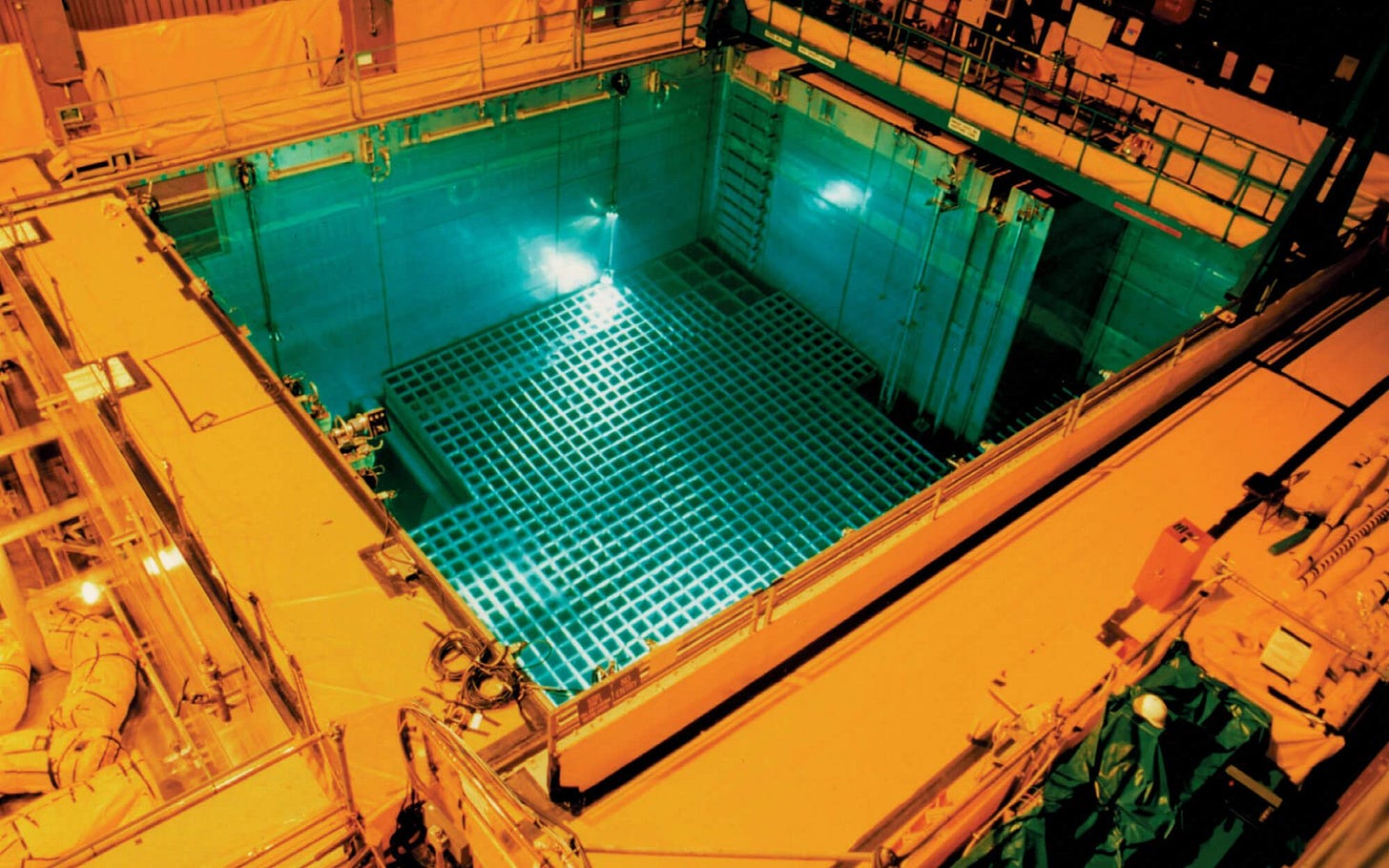

A detailed analysis by the Idaho National Laboratory compared waste metrics of an SMR (NuScale VOYGR) to a reference large PWR. It found that NuScale’s design would generate about 1.1 times the mass and volume of spent fuel per gigawatt-hour as a large reactor due to slightly lower fuel burnup and efficiency. Sourc. In other words, SMRs might be slightly less fuel-efficient, meaning a bit more waste per energy, but on the order of 10% difference. For context, a 300 MWe SMR operating at 90% capacity might discharge on the order of 6–7 metric tons of spent fuel each year (since a 1 GWe plant produces ~21.7 tons/yr, and 300 MWe is 0.3 GWe) Source Source. That’s roughly 1 or 2 casks worth of fuel annually. Over a 60-year life, one SMR unit could generate on the order of 400 tons of SNF. This is not a trivial amount, but in absolute terms smaller than a single large reactor’s lifetime SNF (which might be ~600–700 tons). Either way, the requirement remains: spent fuel must be safely stored and ultimately disposed of.

Interim storage: All these SMRs would have on-site spent fuel pools and eventually dry cask storage, just like current plants. One advantage of SMRs is that their smaller core inventories might allow longer storage in the pool before needing to offload to dry casks. For example, NuScale’s plant design includes a pool that can hold 10+ years of spent fuel for all modules. This means Colorado Springs could keep the spent fuel on site securely for decades, awaiting a long-term solution. The fuel assemblies themselves in SMRs are often similar in size to existing ones (e.g., NuScale uses short PWR-like assemblies, BWRX-300 uses BWR assemblies slightly modified). So the dry storage systems would be essentially the same technology as used at other reactor sites – a well-understood practice.

Fuel usage and enrichment: The LWR-based SMRs use fuel enriched below 5% in U-235. This is the same enrichment as current reactors. They achieve similar burnup (around 50 GWd/t), though NuScale’s smaller core has slightly lower burnup (~49 GWd/t) and shorter refueling intervals. More frequent refueling can mean more frequent downtime and more batches of spent fuel, but also allows flexibility in fuel management (e.g., utility can schedule refueling in spring when electricity demand is low).

Waste characteristics: The radiological characteristics of the spent fuel from SMRs are very similar to that of large PWR fuel – mainly, it’s high-level radioactive material that needs shielding and cooling initially, and long-term isolation for thousands of years. The INL study noted only minor differences: NuScale’s spent fuel has slightly higher immediate decay heat and radioactivity per ton (because of lower burnup) but not significantly so. Source After 10 or 100 years, the activity of SMR fuel and large reactor fuel are in the same ballpark This means from a repository perspective, disposing of SMR spent fuel is essentially the same challenge as existing LWR fuel. It’s still awaiting a geological repository solution in the U.S. Since SMRs don’t fundamentally change the fuel type, they inherit the same back-end issue: the need for a long-term disposal path (e.g., Yucca Mountain or an interim storage or advanced reprocessing if that ever comes).

One talking point sometimes raised is that SMRs, if deployed in large numbers, could increase the volume of nuclear waste per energy generated, simply because their fuel usage isn’t drastically more efficient and they might be more widely distributed. A study from Stanford/University of British Columbia in 2022 suggested some SMR designs could even produce more volumetric waste (due to things like different fuel geometries or more activation of structural materials). Source Source In our case, all five designs are thermal-spectrum LWRs, so they don’t have exotic fuel cycles that would create radically more or less waste. The X-Energy and Natrium designs (which are advanced reactor SMRs not on our main list) illustrate how different tech can change waste: Natrium (sodium fast reactor) achieves very high fuel burnup and thus produces only ~28% of the SNF mass per GWh compared to an LWR Source, whereas a pebble-bed like Xe-100 produces low mass but a lot of low-density graphite waste. But for NuScale, GEH, Holtec, Westinghouse, Rolls, we can safely say each produces on the order of 20–25 tons of SNF per GWe-year, which is standard. Source For a single 300 MWe unit, that normalizes to ~6–8 tons per year as mentioned.

Decommissioning waste: Another aspect of “waste” is what happens at end-of-life of the plant. After 60 (or maybe 80) years of operation, the reactor itself and associated components will become low-level radioactive waste from activation (steel, concrete, etc. that has neutron-induced radioactivity). Smaller reactors mean less mass of material to dispose of, but if many units are built, there will be many reactor vessels to cut up eventually. The INL waste study compared decommissioning waste volumes and found the total low-level waste from a NuScale 12-pack was actually slightly less per GWe-year than a reference PWR (due to compact size), but with more of it classified as GTCC (Greater-Than-Class-C) waste which requires deep disposalSource Source. GTCC waste includes very activated core components. NuScale’s modular design means more reactor pressure vessels (one per module), which could lead to a higher volume of GTCC steel to dispose. For one AP300 or Rolls SMR, it’s one big vessel similar to today’s, so likely similar decommissioning waste profile as a large plant, just scaled by power. These are considerations far in the future, but regulators do require a decommissioning fund plan as part of licensing. Colorado Springs Utilities would need to save for eventual dismantlement, just as it does for decommissioning of coal infrastructure (though nuclear decomm is costlier).

In practical terms, spent fuel from an SMR would be handled on-site in the same manner as at existing nuclear plants. It can be safely stored in dry casks for many decades (there are already plants that have kept spent fuel on site for 40+ years in pools and casks). If a consolidated interim storage facility opens in the U.S. (there are proposals in New Mexico and West Texas, ironically involving Holtec for one), Colorado Springs could ship its spent fuel there in the future. Or if Yucca Mountain or another repository comes online in mid-century, the fuel would go there. Until then, any SMR project here would include building a secure fuel storage installation. The public will want assurance on this point: that even if a plant shuts down, the waste won’t be stranded unsafely. Fortunately, the technology and regulatory framework for on-site storage is very mature – the NRC has licensed dry cask systems that can store fuel for 100 years or more with minimal maintenance.

“Front End” Nuclear Waste

In discussions of nuclear waste, most attention is rightly focused on spent fuel, but the front end of the fuel cycle—especially uranium mining and enrichment—also generates significant environmental impacts. In Colorado, this issue carries particular weight due to the state’s long and complicated history with hardrock mining. Legacy contamination from uranium mills and mine tailings continues to affect areas like Uravan and Cañon City, leaving a residue of environmental distrust. For any new nuclear project to gain political and public support in Colorado, these front-end impacts must be taken seriously and addressed transparently.

Uranium mining generates large volumes of tailings, which are the crushed rock left over after uranium is chemically extracted from ore. These tailings still contain radioactive materials like thorium-230 and radium-226, which can persist for thousands of years. If improperly managed, they can contaminate soil, groundwater, and rivers.

Enrichment—the process that increases the concentration of U-235 in uranium fuel—also produces depleted uranium as a byproduct. The United States currently has more than 700,000 metric tons of depleted uranium stockpiled, much of it stored indefinitely. Although some advanced reactor concepts propose reusing this material as fuel, the light water SMRs under consideration in Colorado still rely on conventional enrichment methods that increase the burden of front-end waste.

Reducing the environmental impact of the front end must be part of any responsible nuclear strategy. This includes sourcing uranium from well-regulated suppliers, ensuring strong oversight of mill waste disposal, and advocating for sustainable fuel cycle practices, including long-term stewardship of depleted uranium. While SMRs may offer advantages in safety and scalability, their fuel still comes with upstream costs. A credible path to nuclear development in Colorado must acknowledge and address these legacy issues—not just at the back end of the fuel cycle, but at the beginning as well.

SMR Construction

One of the key promises of SMRs is modularity – not just in technology but in project delivery. Traditional large reactors (like a single 1,100 MWe AP1000) are megaprojects that require a decade-long commitment and billions spent before any power is generated. SMRs aim to change that paradigm by enabling phased construction and deployment in increments. This could be very advantageous for a city utility like Colorado Springs.

Phased capacity expansion: With SMRs, a utility can install capacity in smaller chunks to better match demand growth and financing capability. For example, instead of building 1000 MWe all at once, CSU could build 100–300 MWe at a time. In the case of NuScale, they could start with 4 modules (~308 MWe), then add 2 more later (up to 462 MWe), and so on up to 12 modules. Each module could potentially come online as it’s completed (staggered by a few months each) – so revenue from the first modules could help fund later ones. This modular scaling reduces the risk of over-building capacity and straining the utility’s budget. It aligns well with how municipal utilities plan incrementally.

By contrast, if one were to build an AP1000 (1100 MWe), you get no power until the entire thing is done, and you might end up with surplus capacity initially. For Colorado Springs (current peak demand around 1,000 MW), dropping in a 1100 MWe plant would overshoot. An SMR’s smaller size is more “right-sized” and can be added in steps.

Shorter construction durations: Historically, nuclear projects suffered from schedule slippage because of their complexity and custom nature. SMRs intend to break that by shifting work to factories. The phased approach also extends to construction sequencing: even if a site will ultimately host, say, four units, you can stagger their construction starts so that lessons learned from the first apply to the second, workforce can move unit to unit, and financing can be staged. For example, you pour the foundation for unit 1 and unit 2 initially, but you might not start unit 2’s nuclear installation until unit 1 is well along. This is somewhat how South Korea built batches of its reactors (staggered by a year each).

Learning curve and replication: SMR vendors are banking on the idea that building 10 identical 300 MWe reactors will eventually be far cheaper and faster per unit than building one 3000 MWe mega-project. The analogy is often made to shipbuilding or aircraft manufacturing. With large reactors, each one was essentially a one-off design or had site-specific variations. SMRs are meant to be cookie-cutter. So the first few might be expensive, but by the time you get to the 5th, 6th unit, the costs drop sharply and construction becomes routine. Westinghouse’s AP300, Holtec, and Rolls-Royce explicitly follow this strategy of minimal design changes and replication to drive economies of series. Source For Colorado Springs, it could mean that if we’re not the first adopter, we can benefit from cost reductions achieved by earlier builds elsewhere.

Risk reduction: Phased construction also reduces financial and project risk. If something goes wrong or requirements change mid-project, having smaller increments limits the exposure. For example, suppose after building two SMR units, there’s a major change (like power demand flattens or a new tech emerges) – the utility could pause or slow further additions. With a giant reactor, you’re all-in and can’t really adjust midstream without leaving an unfinished plant. This adaptability is valuable in the uncertain energy transition landscape.

Comparison to AP1000 (large LWR): The AP1000 projects highlighted the challenges of gigawatt-scale builds – Vogtle’s units in Georgia went far over budget and schedule (partly due to FOAK issues with modular construction at that large scale). One might say: if we can’t manage one big reactor well, maybe we can manage a set of smaller ones better. The counterargument is that multiple small units could increase complexity (you have more reactors to oversee, more components in total). But the SMR designers have tried to simplify each unit so much that even managing 12 NuScale modules is supposed to be easier than one big unit (NuScale’s entire 12-pack control room can be operated by a handful of operators and automated systems). Phased deployment also means you can integrate lessons from other industries. For instance, in combined-cycle gas plants, it’s common to build two or four smaller turbines rather than one huge one, to allow maintenance one at a time and phased installation – SMRs bring that concept to nuclear.

Of course, one must manage the logistics of modular building: it requires an efficient supply chain to deliver modules on time, and skilled labor for assembly. It also means dealing with regulatory inspections for multiple units, which the NRC is preparing for. The NRC have to inspect each module’s construction quality, etc., but they can also streamline some oversight when many identical components are used.

In contrast to the phased, modular approach of SMRs, a traditional large reactor project is all about site-specific execution of a huge design, which has proven challenging in the U.S. in recent decades. Many see SMRs as a way to restore predictability to nuclear construction by breaking the task into smaller, more manageable pieces. We should be candid that this is an expectation that still needs to be proven – the first SMR projects will test whether the reality lives up to the theory. But if they succeed, Colorado Springs can leverage those new best practices.

In conclusion on this point, SMRs offer scalability and flexibility in deployment that align well with a mid-sized utility’s needs. The phased construction strategy could help de-risk the project financially and technically. It is essentially a return to building blocks, as opposed to betting the farm on one monolith. This incremental approach, coupled with standardized design, is what differentiates SMRs from the large nuclear of the past and could make the difference in making nuclear power palatable again for communities like Colorado Springs.

Conclusion

Small modular reactors (SMRs) come in a variety of designs, each reflecting different engineering philosophies, safety approaches, cooling strategies, and deployment models. Some prioritize passive safety and factory modularity; others emphasize high power density or compatibility with air cooling. These design trade-offs matter—and will shape how well a particular reactor fits Colorado Springs' climate, grid needs, workforce, and long-term water stewardship goals.

As the city explores its energy future, Colorado Springs Utilities should evaluate all credible SMR options with a clear-eyed focus on sustainability, flexibility, and cost-effectiveness. No single design is perfect, and the right choice will balance technical fit with long-term reliability and community values. Clean, carbon-free electricity from nuclear energy can play a key role in achieving the city’s energy goals, but only if deployed with care, transparency, and a commitment to responsible resource management.

Sources

Colorado House Bill 25-1040: Legislation concerning advanced nuclear energy development in Colorado.

Colorado Springs Utilities Board Meeting Minutes (February 2025): Details the decision to explore nuclear options in the Electric Integrated Resource Plan (EIRP).

Colorado Utility Looking at Adding Nuclear Power to Fleet: An overview of Colorado Springs Utilities' consideration of nuclear energy.

Feasibility of Air-Cooled Condenser for AP1000: A 2009 NRC study assessing the challenges of adapting the AP1000 reactor design to air-cooled systems. NRC Web

2022 Water Efficiency Plan - Colorado Springs Utilities: Outlines water usage statistics and conservation strategies for Colorado Springs. Colorado Springs Utilities

News 5 In Depth: Supplying Water for Growth in Colorado Springs: Discusses water consumption trends and conservation efforts in the city. KOAA News 5

Fryingpan–Arkansas Project: Provides context on water diversion projects supplying Colorado Springs. Wikipedia

AP1000 Nuclear Power Plant BAT Assessment: Details on the AP1000 reactor design and its environmental considerations. Wikipedia

AP1000 (Wikipedia): General information on the AP1000 reactor design.

U.S. Department of Energy – NRC Certifies First U.S. Small Modular Reactor Design

Details the NRC's certification of NuScale's SMR design, highlighting its passive safety features and modular approach.

Energy.govNuScale Power – Smarter Energy Fact Sheet

Provides an overview of the NuScale Power Module™ capabilities, emphasizing its scalable design and safety mechanisms.

nuscalepower.com

GE Vernova – BWRX-300 Small Modular Reactor

Outlines the design features of the BWRX-300, including its natural circulation cooling and passive safety systems.

GevernovaGE Vernova – BWRX-300 General Description (PDF)

Provides a comprehensive technical description of the BWRX-300 reactor, detailing its operational parameters and safety features.

Gevernova

Holtec International – SMR-300 Brochure (PDF)

Presents the specifications and safety features of the SMR-300, highlighting its passive safety systems and modular construction.

NRC Web+10Holtec International+10Holtec International+10Holtec International – SMR-300 Technical Bulletin (PDF)

Discusses the SMR-300's design philosophy, including its "walk-away safe" operation and integration with thermal energy storage.

Holtec International+2Holtec International+2Holtec International+2

Westinghouse Nuclear – AP300™ SMR

Describes the AP300's design, based on the proven AP1000 technology, and its passive safety features.

navigator-voyantstudios.com+4Westinghouse Nuclear+4Westinghouse Nuclear+4Westinghouse Nuclear – AP300 SMR Data Sheet

Provides detailed technical specifications of the AP300, including its thermal output and safety systems.

Rolls-Royce SMR – Our Technology

Outlines the design and capabilities of the Rolls-Royce SMR, emphasizing its modular construction and power output.

Office for Nuclear Regulation+7theguardian.com+7Wikipedia+7Rolls-Royce SMR – Official Website

Provides comprehensive information on the Rolls-Royce SMR project, including its development timeline and deployment plans.

zh.wikipedia.org+4GOV.UK+4